High quality gas springs from FA Krosno provide comfort and safety in countless applications in our daily life. They are designed to reduce human effort to open lids and lift hatches whilst making cover movements smooth and controlled. Quality components and robust design make our gas springs a reliable companion for many years. Our gas springs are fully tested before they leave the factory to ensure that all customer specifications are met. This is yet another step that guarantees the perfect quality of our products. When designing applications that incorporate gas springs, please observe essential principles which are the basis for safe and long-lasting use.

Gas springs with hydraulic and dynamic damping

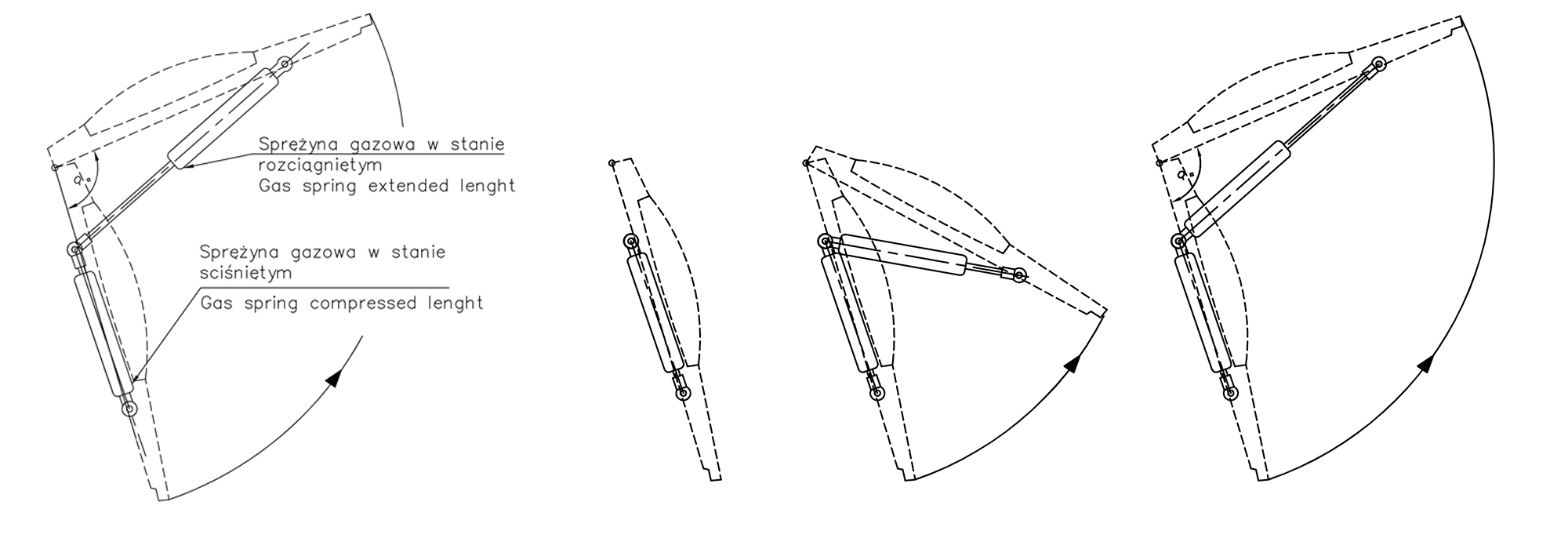

Gas Springs are made as set of pressure gas cylinder and piston rod with wide variety of fitting ends depending on mounting and type of work. The gas spring’s force (F1) corresponds to the nitrogen pressure in a cylinder multiplied by surface of piston rod section. FA Krosno offers two types of gas springs (gas struts) – with hydraulic and dynamic damping. The gas spring with dynamic damping slows down very smoothly what makes the flap or other lifted object to stop very gently. In case of hydraulic damping, gas springs slow down in more rapid manner, however equally efficiently. One of the most crucial differences between the two types of gas springs is the way of proper installation. Gas springs with dynamic damping can be installed in any position whereas gas springs with hydraulic damping, to make them work properly, should be installed with piston rod downwards. Both types have its own applications. The damping type can be chosen according to customer’s needs. Gas springs differ also with such parameters as: length, stroke, force, diameter of the cylinder, diameter of the piston rod.

How to find the proper parameters of a gas spring

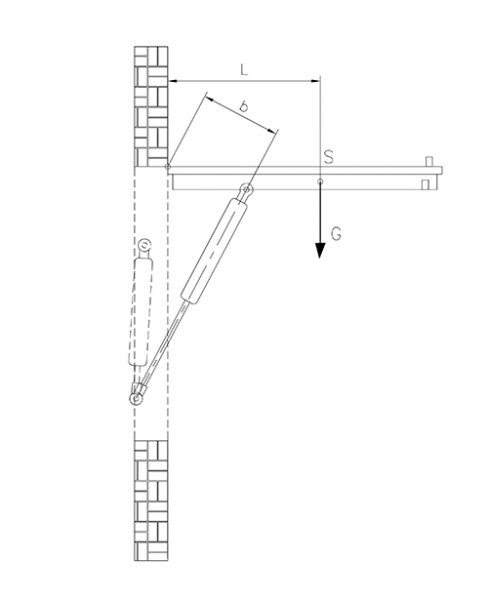

Please specify: – weight of the flap W in kilograms – approximate – length to the center of gravity of the flap L (distance from the axis of the hinge to the center of the flap in the open state) – distance E between the point of fixing the gas spring to the flap and the axis of its rotation – quantity of gas springs n (usually 2pcs) – approximate calculation for needed F1 force: F1=((W*L*9,81) / (E*n))* 1,2 – having the required stroke (difference in the distance between the spring fixing points in the opened and closed state of the flap) and F1 force the appropriate spring from the catalogue can be chosen

Safety and handling

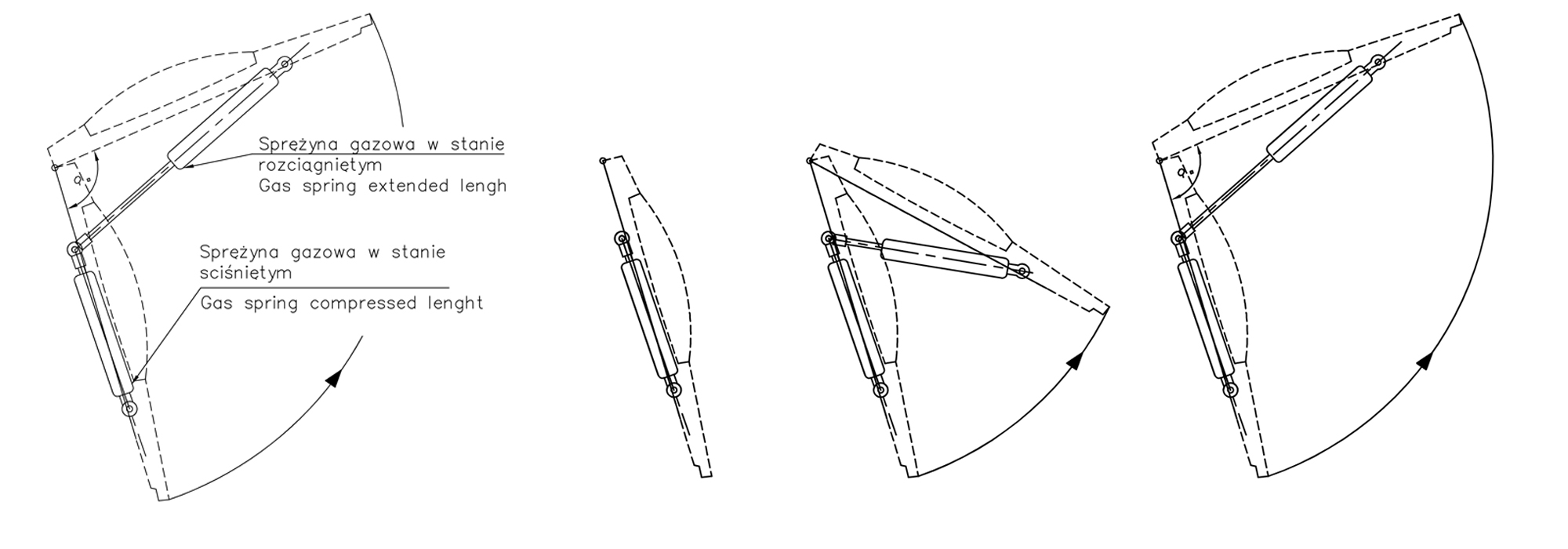

High quality gas springs from FA Krosno provide comfort and safety in countless applications in our daily life. They are designed to reduce human effort to open and lift hatches whilst making cover movements smooth and controlled. Quality components and robust design make our gas springs a reliable companion for many years. Our gas springs are fully tested before they leave the factory to ensure that all customer specifications are met. This is yet another step that guarantees the perfect quality of our products. When designing applications that incorporate gas springs, please observe essential principles which are the basis for safe and long-lasting use. When designing applications that incorporate gas springs, please observe essential principles which are the basis for safe and long-lasting use. – Never attempt to open a gas spring or change the design. Gas springs are filled with nitrogen, which is safe in itself but, because it can be compressed up to 200 bars in the spring, any action leading to release of pressure can cause death, serious personal injury or property damage. The same applies to improper selection and use of the products described herein or related items. – Standard gas springs are designed for use in the temperature range from -30°C to +80°C. For other temperature ranges we offer special gas springs. – Our products are designed to withstand tens of thousands of cycles in standard conditions. The service life of a gas spring depends on many external factors such as temperature, humidity and environmental conditions. – Our gas springs are maintenance-free. Do not oil or grease a piston rod. – Gas springs cannot be subjected to transverse forces, tensile forces especially over maximum extension, vibrations, oscillations or high temperatures. – Gas springs cannot function as an end stop. To limit the maximum opening the appropriate end stop must be used. – The proper functioning of gas springs is primarily ensured by proper sealing and piston rod surface, which together guarantee that gas pressure inside the cylinder is maintained. Any mechanical damage of a piston rod surface can lead to loss of functionality. Therefore protect the piston rod against knocks, dirt, scratches and paint. – Installation of gas springs which have visible damage and / or are incomplete is not permitted. – Gas springs cannot be subject to any modifications (e.g. shortening, lengthening, welding), interferences with the spring construction, heating, grinding, opening or drilling, removal of prints, replacement of fasteners, etc. – The gas spring should be assembled and disassembled in a stretched condition according to the sketches presented. It is not permissible dismantle the compressed or partially compressed spring. Recommended installation mode for hydraulic damping gas springs

Recommended installation mode for dynamic damping gas springs

Disassembling of ball socket Insert a screwdriver (approx. 5 mm wide) into the space between the metal clip and the mounting. Raise the clip sufficiently to lift the mounting off the ball stud

Transport and storage

– It is not permissible to store gas springs in the same room as caustic, oxidizing materials and other materials which affect condition. – It is recommended to store gas springs in roofed rooms that protect against atmospheric influences (in temperature 5 – 35° C and relative humidity ≤70%). – It is recommended to store the springs in a vertical position with the piston rod pointing downwards. – Gas springs must be transported by covered means of transport. – Gas springs must be protected against damage during transport.